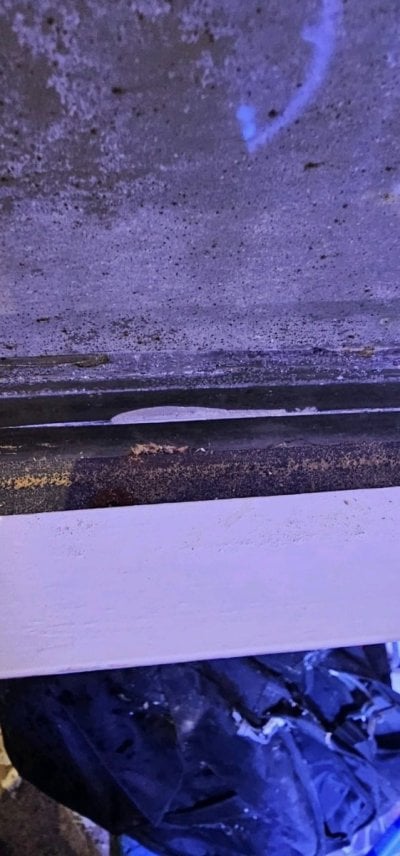

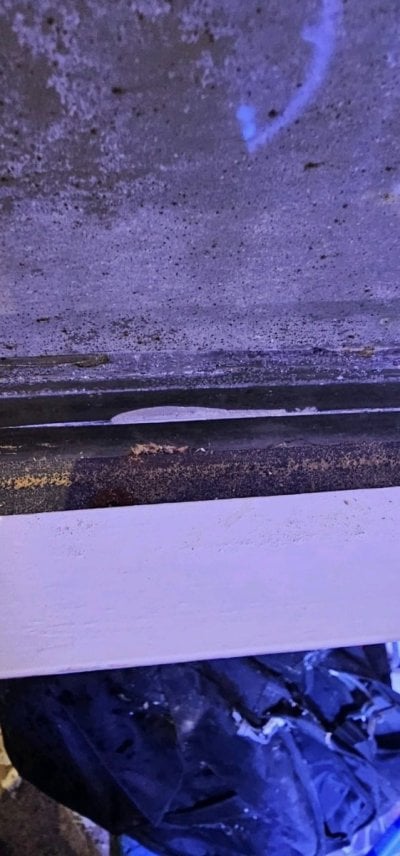

I have a 360. 3/4 Inch acrylic. I have a seam bubble of sorts that has formed in the front pane. I had another small one prior to and decided it was best to play it safe and install 3/4 triangle rod on the inside. Over the past year this has formed. I tried to have weldon 4 seap into the defect but it would not. So question. Should I use a small drill bit and lightly drill the seam and try to insert weldon 4 that way, leave it alone since there is already triangle rod on the inside or should I glue a strip of 3/4 by 1 on the outside as well. Tank was full temporarily empty to inspect inside seams of triangle rod (just in case)

Thanks in advance

Thanks in advance