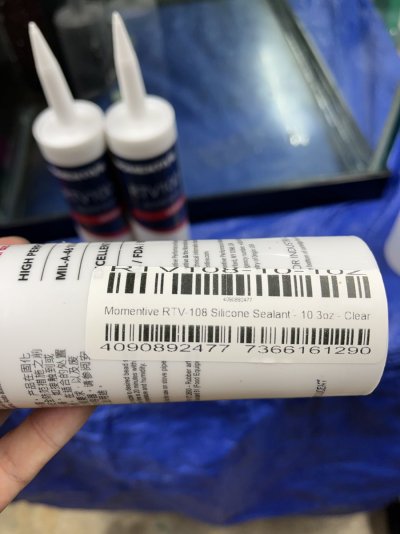

I just picked up a used 90G (rimmed) with acrylic sump for a decent price. This will be a long slow process for me (probably at least a year before I have it up and running as I need to accumulate the sump equipment, build the stand, cycle more rock, etc.). It is currently sitting in my truck bed, until I can get a friend to come help me move it into my workshop where it will be for the next month at least. I got the tank from my LFS, it was one of their display tanks they took down while consolidating their saltwater portion of the store. I know it does not leak (so the seams are good); however, the silicone on the interior corners has seen better days, I am guess their algae scraper did a number on it. I intend for the tank to be up for the foreseeable future, so I might as well do it now while all my fish and corals are happy in their current tanks (and not wait for it to become an emergency in 5-10 years). My first plan is to thoroughly clean the tank and then build up the courage to redo the inner seals (not the seams). I intend to use RTV 108 for the silicone and one of the silicone/caulking beading tools, I will update as I progress on this front.

In the meantime, I have begun to plan out my stand. I mocked up the tank in SketchUp, and built my stand around it. Currently it will be 54" from the floor to the top of the tank rim which is about what my WaterBox 50.3 is right now. I didn't want to go any taller as I would prefer to not need a step stool when working in the tank. Construction will be 2x4, 2x6, and a 3/4" birch plywood top with a 1/4" chamfer. Joints will be TiteBond III and pocket holes/screws using a Kreg jig. I have planned for a 1/2" lip on the backside of the tank, and a 1" lip on the front and sides. The 1/2" lip on the back is to make sure my drain lines clear. I will leave the back of the stand open as I am going to plumb through the wall and put my sump in the room behind my tank. The sides will be closed off with bead board (not shown in SketchUp). I will make cabinet doors for the front, and put plywood in the bottom for general storage. The cabinet doors may be further down the road once I can make it down to my parent's and make use of my dad's shaper to make some raised panels. I will prime the stand with Zinsser bullseye, then use a semi-gloss white paint. I will not have a canopy. I will start on the stand once I have resealed and leak tested the tank.

The overflow is drilled with two holes, one 1-3/4" diameter hole, and one 1-1/2" diameter hole. My assumption is it was drilled for a durso overflow with one drain and one return line. My goal is to plumb it for a herbie over flow, and run my return lines over the top of the tank like this:

www.reef2reef.com

www.reef2reef.com

I currently have no idea how I want to setup the sump yet as all my current tanks are AIO or using an HOB. I will be plumbing my 10G frag tank into it, and would like to have a fuge. I may split my drain line and run a separate fuge that sits below my DT and above the sump. The acrylic sump is 36" long, and 13.5" wide, 16" tall, so approx 33g. I may end up tearing down my FW 20g L and convert that to the frag tank, and use my 10G as the fuge. I have some time before I have to decide on this though.

My goal is to end up with one system in the house and only one DT, as opposed to the 4 separate tanks I am running right now. I will update as I make progress on the cleaning, silicone, and leak testing. If that goes well, I will move onto the stand. After the stand, I will start watching the used market and BRS openbox/sales for sump equipment as I plan out the sump build.

In the meantime, I have begun to plan out my stand. I mocked up the tank in SketchUp, and built my stand around it. Currently it will be 54" from the floor to the top of the tank rim which is about what my WaterBox 50.3 is right now. I didn't want to go any taller as I would prefer to not need a step stool when working in the tank. Construction will be 2x4, 2x6, and a 3/4" birch plywood top with a 1/4" chamfer. Joints will be TiteBond III and pocket holes/screws using a Kreg jig. I have planned for a 1/2" lip on the backside of the tank, and a 1" lip on the front and sides. The 1/2" lip on the back is to make sure my drain lines clear. I will leave the back of the stand open as I am going to plumb through the wall and put my sump in the room behind my tank. The sides will be closed off with bead board (not shown in SketchUp). I will make cabinet doors for the front, and put plywood in the bottom for general storage. The cabinet doors may be further down the road once I can make it down to my parent's and make use of my dad's shaper to make some raised panels. I will prime the stand with Zinsser bullseye, then use a semi-gloss white paint. I will not have a canopy. I will start on the stand once I have resealed and leak tested the tank.

The overflow is drilled with two holes, one 1-3/4" diameter hole, and one 1-1/2" diameter hole. My assumption is it was drilled for a durso overflow with one drain and one return line. My goal is to plumb it for a herbie over flow, and run my return lines over the top of the tank like this:

Thoughts on drilled returns vs going over the rim?

Am currently in the design phase of my build and was wondering what everyones opinions are on going over the top rim of the tank vs drilling for returns? why?

www.reef2reef.com

www.reef2reef.com

I currently have no idea how I want to setup the sump yet as all my current tanks are AIO or using an HOB. I will be plumbing my 10G frag tank into it, and would like to have a fuge. I may split my drain line and run a separate fuge that sits below my DT and above the sump. The acrylic sump is 36" long, and 13.5" wide, 16" tall, so approx 33g. I may end up tearing down my FW 20g L and convert that to the frag tank, and use my 10G as the fuge. I have some time before I have to decide on this though.

My goal is to end up with one system in the house and only one DT, as opposed to the 4 separate tanks I am running right now. I will update as I make progress on the cleaning, silicone, and leak testing. If that goes well, I will move onto the stand. After the stand, I will start watching the used market and BRS openbox/sales for sump equipment as I plan out the sump build.

Last edited: