This article is an overview and instructions for building a DIY Auto Frozen Feeder for your Aquarium.

What does it do?

This feeder was built so I can get away from Home and continue to feed my fish. I have a few Ehiem Pellet Flake Auto Feeders that I use while away. The issue is I have a Copperband Butterfly fish in each of my Tanks that won't eat Flake or Pellet Food (ie. strictly eat Frozen). After building and installing this feeder it works so well, I've set it up as a permanent Daily Feeder which now gives me near total hands off Automation on all my 4 tanks.

The feeder may look like a complex time machine that runs on a flux capacitor made to fit into the trunk of your DeLorean but you don’t have to wait for the future…it’s actually quite simple once you understand the basic concepts and you can make one for yourself.

I did NOT make the Koolatron (which is a purchase DC voltage Cooler for your Car). Plenty of models, sizes and prices to choose from.

Here is the one I used that I had spare.

This lower price model might work for a Single Tank Feeder.

I also did NOT make the Magnetic Stirrer.

I did make my doser, but you can buy your own DOSER too. LIke this one if building a Single Tank Feeder.

The rest I made with parts I had kicking around.

Let's move on.....

Want to get a quick Video overview DEMO before you read all the details in this Article.....

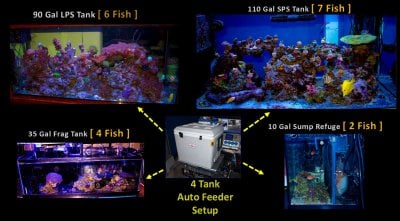

The feeder designed and discussed here was designed to feed my four tanks (as shown below), yet it will work just as well for a single tank or more than four Tanks. It’s determined by the number of dosing heads.

In an effort to make this easier to understand, here is a basic diagram showing the final design and components used. The setup and functionality are described below. I will refer to this diagram throughout the article.

Preparation/Overview:

Feeding Steps

Optional: I chose to use a magnetic mixer to stir the feeding concentrate prior to each feeding cycle. After testing the feeder I learned that it does make feeding more consistant, but not really necessary if you want to cut on Costs or Space.

Dosing Pumps Flows

Cleaning and Purging Steps

The Full Feed Cycle Illustrated:

NOTE: The final cleaning and purging step is an important element in the design. All the food and tubes within the cooler are chilled. The tubes going to the fish tanks are obviously not. If there is trapped food in the feeding tubes going to the tank(s) it has the potential to spoil in between feedings since they are not temperature controlled. This is true even if the distance between your feeder and tank is very short. Please do not skip the cleaning and purging steps.

Doser Heads and Connections:

Whether you’re working with one tank or multiple, your design will have to accommodate having at least one dosing head (D1) located inside the cooler. Since that dosing head is transferring the concentrate there is no way to flush/purge that line after each use, therefore it needs to stay cooled.

Since my particular auto feeder is feeding multiple tanks, I was unable to fit multiple dosing heads inside the cooler. With some basic electronic wiring skills, you can remove dosing heads form any multi-headed doser and extend the wires. If only designing the auto feeder for one tank, most smaller three-headed dosers will likely fit in your cooler. This is something to keep in mind when designing your system.

In the picture below of my prototype, it illustrates how the doser heads are configured – one internal and the others external to the cooler. The magnetic stirrer, three containers and one dosing head are inside the cooler.

Programming Dosers:

The programming will vary with each setup and it unique to each feeder. So it’s not reasonable to discuss all the options and maintain your interest. But here are a few key factors to consider when doing your programming:

Now for some programming Details:

NOTE: [The Dose 5] (Clean/Purge/Flush) should be about double the length of the tube (distance to the tank). This ensures the line is not only clear of FOOD & Flush Water, but the tubes are purged and only full of air until the next feeding.

I also learned during testing that you don't need to add that much water (to completely fill the Tube Length) for the flush, since when water runs out the flush will continue with Air, and flush out the ALL the water anyway. (This saves on the size of the Water Container).

Components and Assembly

Let’s discuss what actually makes this thing work so well. In my case, I was able to utilize things I had on hand at the house. I’ll share some photos of the parts and the assembly components.

I’ll start by sharing some photos of the feeder disassembled.

For the containers that will handle the food (Items A and C in the first diagram), you want to find something that has a funnel shape to it. This will assure the food settles near the bottom of the container which is where the dosing pumps tubes connect. In my case, I used an Iced Tea Bottle, installed upside down. The cap is the perfect size for the magnetic stir impeller. The other added benefit is it is easily replaced if/when the gunk builds up. I love Iced Tea so I don’t mind having another bottle to keep the feeder fresh and clean.

The top off water container (Item B in the first diagram) I used a Kamoer Dosing Container. It’s a large volume container and with its rectangular shape, it fits perfectly in the cooler.

The bottom of the cooler has egg crate that the Electronic Magnetic Stirrer sits on. Having the Stirrer up off the actual bottom of the cooler protects it from any accidental spill or liquid condensation that settles on the bottom. (NOTE: The more you open and peek into the Cooler, warm moist air will get into the cooler, and the more you will get condenstate dripping off the Cold Cooling Fins and containers)

Since we all have some Styrofoam lying around from our last fish or coral order, I discovered it works perfectly for mounting equipment and positioning things correctly and firmly in place. Just cut pieces to fit your varying conditions. Nothing is glued and installed permanently. As long as it fits snuggly it’s not going anywhere and it makes things easier to take apart for the occasional cleaning and/or maintenance.

I used wider diameter and stiffer RO tubing for the dosing line HOLDERS. Just cut some slits in the STIFF RO TUBING mentioned above and use a drop or two of hot glue to hold in place. The softer Air Line tubing will snap in. Try to keep from installing anything permanently as mentioned above. The same stiffer tubing was used to position the floppy tube at the bottom of the Concentrate Container in an effort to keep the tube on the bottom of the container at all times. This is important so it doesn’t get out of position during the stir.

Important to note, if you’re using tubing couplers you may need to enlarge the whole so you don’t end up with food getting lodged in the couplers. In my case, the couplers were too narrow so I drilled them out to enlarge the holes.

Don’t forget to enlarge the tube couplers if necessary

Here is a quick overview on the OPTIONAL Magenetic Stirrer Setup, if you choose to add one to your design.

So you need to turn it on every so often, and most importantly a minute before the Feeding Cycle starts. This will ensure the food concentrate is evenly distrubuted and each feeding is consistant. Otherwise your early feeding will be heavier, and the last feeding will be light. It's not perfect but that's the idea.

Since your Doser can't control the Magentic Stirrer, you can use a timer, and the program your stir and feed accordingly.

Okay, so we have our Auto Feeder set up, it’s time to run the lines to the tank(s). Then you'll have to adjust your Flush program once you finalized the tube lengths to your tank. ( Remember the last program is the purge and is distance dependant )

This is my setup as seen from the Back of the Cooler.

You need to consider where the feeding output tube is installed in your tank(s). It’s important to make sure the food is either spread throughout the tank or I a feeding ring so the inhabitants can crab it before the overflow does.

I do have a feeding ring on one of my tanks so that’s where the output tube is installed. On another tank which doesn’t have a feeding ring, I placed the output tube right in front of a power head.

The other two tanks are too far from the auto feeder and would require a very long tube to reach them on the floor above the sumps. I’m lucky that both sumps are in the basement and close to the feeder. For those two, I simply placed the output tube (under water) next to the return pump inlet . The return pump takes care of the rest.

Feeding Output tube installed at the input of the return pump and the food is pumped to the tank Upstairs.

To close, I thought I’d share a couple ideas I had that I didn’t implement. I figured I’d share them in case a reader decides to build their own Auto Feeder and may be able to incorporate some different ideas. These additional concepts as well as designs other folks come up with can be discussed in the comments.

That covers off all I wanted to convey on the feeder design.

Summary:

I have been running the feeder for a couple of weeks and it works perfect. The longest I ran it unattended was 5 days while away from home, and it almost ran out of food and water. So I'm working fine tuning the Food Concentrate Concentration, and fine tuning the dilution and flush amounts to last longer.

The feeder airline tubes are perfectly clean with the flushing cycle, even my longest run which is 12 feet to my sump that sends food via the return pump to my upstairs tank.

The ONLY DOWNSIDE I see after running the Frozen Feeder for a while is the Fish have become trained on it, and now the fish love it more than me They sense the food is coming and hang around the feeder output spots. They don't freak out as much every time they see me going to the Fridge, or get close to the tank. At least they don't beg so that means I'm not suckered into feeding them too much. The feeder runs regularily few times a day and same small portions.

They sense the food is coming and hang around the feeder output spots. They don't freak out as much every time they see me going to the Fridge, or get close to the tank. At least they don't beg so that means I'm not suckered into feeding them too much. The feeder runs regularily few times a day and same small portions.

What does it do?

- It Feeds "Chilled...Always Fresh" Frozen Food to my 4 Fish Tanks Automatically.

- Programmable "Variable Sized" Portions.

- Programmable "Any time of day" Feedings.

- Self Cleaning too!

This feeder was built so I can get away from Home and continue to feed my fish. I have a few Ehiem Pellet Flake Auto Feeders that I use while away. The issue is I have a Copperband Butterfly fish in each of my Tanks that won't eat Flake or Pellet Food (ie. strictly eat Frozen). After building and installing this feeder it works so well, I've set it up as a permanent Daily Feeder which now gives me near total hands off Automation on all my 4 tanks.

The feeder may look like a complex time machine that runs on a flux capacitor made to fit into the trunk of your DeLorean but you don’t have to wait for the future…it’s actually quite simple once you understand the basic concepts and you can make one for yourself.

The main component of this feeder is a Koolatron Cooler to keep Frozen Food chilled, and it all runs on a few dosing heads. Water is pumped via tubes to get the food to the tank and ultimately to your fish.I did NOT make the Koolatron (which is a purchase DC voltage Cooler for your Car). Plenty of models, sizes and prices to choose from.

Here is the one I used that I had spare.

This lower price model might work for a Single Tank Feeder.

I also did NOT make the Magnetic Stirrer.

I did make my doser, but you can buy your own DOSER too. LIke this one if building a Single Tank Feeder.

The rest I made with parts I had kicking around.

Let's move on.....

A closer look inside the Koolatron with cover removed that contains internal Components.

This article will describe my final design and will discuss some other options you can consider when building your own. Details on materials, construction tips and programming are included.

Want to get a quick Video overview DEMO before you read all the details in this Article.....

The feeder designed and discussed here was designed to feed my four tanks (as shown below), yet it will work just as well for a single tank or more than four Tanks. It’s determined by the number of dosing heads.

In an effort to make this easier to understand, here is a basic diagram showing the final design and components used. The setup and functionality are described below. I will refer to this diagram throughout the article.

- Fill the concentrate container (A) with your favorite frozen food (frozen pieces/cubes or rinsed frozen food in small amount of fresh water).

- Note: the frozen food pieces (after melting) must be smaller than the diameter of the tube you are using to avoid clogging the feeding tubes. You may have to blend your chosen food to ensure the pieces are small enough.

- Top off container (B) is filled with Pure Water since it will be the liquid to distribute food to your tank.

- This same container (B) and water is used to automatically clean and flush out the feeding tubes after each feeding.

- The food from (A) will pumped to the distribution container (C) and then pumped to the tank from there.

- D3,D4-Dn are simple dosing pumps of your choosing. (# of Pumps depends on # Fish Tanks (F) you wish to set up)

Works with Most Frozen Foods (Tested with Mysis, and Brine Shrimp).....Food Can be Rinsed and Strained if desired

Careful to not use Large Chunk Frozen (it can Plug the pumps and tubes)

Coolers Take Time to Cool things down (So add things cold at the Start)

Careful to not use Large Chunk Frozen (it can Plug the pumps and tubes)

Coolers Take Time to Cool things down (So add things cold at the Start)

Feeding Steps

- (optional) Mix Frozen Food Concentrate

- Dosing pump (D1) pumps the frozen concentrate from container (A) and adds it the distribution container (C)

- Dosing pump (D2) pumps fresh water from container (B) to the distribution container (C), to dilute the concentrate.

- At this point, dosing pump (D1-Dn) feed each tank tied in to your system.

Magnetic Stirrer (Food Concentrate Container)

Optional: I chose to use a magnetic mixer to stir the feeding concentrate prior to each feeding cycle. After testing the feeder I learned that it does make feeding more consistant, but not really necessary if you want to cut on Costs or Space.

Dosing Pumps Flows

Cleaning and Purging Steps

- Dosing pump (D2) pumps fresh water from (B) to container (C)

- The feedings pumps (D1-Dn) then pump the fresh water to the tanks to purge the feeding lines

The Full Feed Cycle Illustrated:

As you can see in the Running Demo Photos above, the Distribution Container is relatively Clean of food after Final Rinse and Flush.

NOTE: The final cleaning and purging step is an important element in the design. All the food and tubes within the cooler are chilled. The tubes going to the fish tanks are obviously not. If there is trapped food in the feeding tubes going to the tank(s) it has the potential to spoil in between feedings since they are not temperature controlled. This is true even if the distance between your feeder and tank is very short. Please do not skip the cleaning and purging steps.

Doser Heads and Connections:

Whether you’re working with one tank or multiple, your design will have to accommodate having at least one dosing head (D1) located inside the cooler. Since that dosing head is transferring the concentrate there is no way to flush/purge that line after each use, therefore it needs to stay cooled.

Since my particular auto feeder is feeding multiple tanks, I was unable to fit multiple dosing heads inside the cooler. With some basic electronic wiring skills, you can remove dosing heads form any multi-headed doser and extend the wires. If only designing the auto feeder for one tank, most smaller three-headed dosers will likely fit in your cooler. This is something to keep in mind when designing your system.

In the picture below of my prototype, it illustrates how the doser heads are configured – one internal and the others external to the cooler. The magnetic stirrer, three containers and one dosing head are inside the cooler.

Protoype DIY Frozen Fix Food Feeder

Programming Dosers:

The programming will vary with each setup and it unique to each feeder. So it’s not reasonable to discuss all the options and maintain your interest. But here are a few key factors to consider when doing your programming:

- The amount of food you wish to feed

- The concentration of your prepared food

- Programming can vary on portions/times of feedings (Breakfast, lunch or dinner time)

- Programming can vary by tank as wel

- Dilution water you use

- Distance to tank from auto feeder

Now for some programming Details:

- [DOSE 1: Concentrate Pump D1] – this is where you simply program how much food you will feed the tank(s).

- This dosing amounts will depend on Food Portion Size.

- [DOSE 2: The Dilute WATER PUMP D2]

- Is just enough Dosing volume to loosen up the contrentrate a tiny bit with water. It' a mini first flush of the distribution container.

- [DOSE 3: Feed Pump D3, D4,...]

- Is enough Dosing Volume to COMPLETELY drain the distribution container ( DOSE 1 + DOSE 2)

- You DON'T have to Dose long enough to get Food to the Tank (The Purge Dose 5 will get food there)

- [DOSE 4: Flush WATER PUMP D2]

- In enough Dosing Volume to add some Rinse/Flush Water for Last DOSE 5.

- This Rinses the Distribution Container. So the amount must be a bit more than ( DOSE 1 + DOSE 2)

- [DOSE 5: Clean/Purge Program : FEED PUMP AGAIN D3]

- This Dosing Volume will depend on the distance to your tank. (Roughly = 2x Distance to Tank+DOSE 4)

- You will be dosing any remaining food, Rinse Water, and a push to purge the dosing lines completly.

NOTE: [The Dose 5] (Clean/Purge/Flush) should be about double the length of the tube (distance to the tank). This ensures the line is not only clear of FOOD & Flush Water, but the tubes are purged and only full of air until the next feeding.

I also learned during testing that you don't need to add that much water (to completely fill the Tube Length) for the flush, since when water runs out the flush will continue with Air, and flush out the ALL the water anyway. (This saves on the size of the Water Container).

Components and Assembly

Let’s discuss what actually makes this thing work so well. In my case, I was able to utilize things I had on hand at the house. I’ll share some photos of the parts and the assembly components.

I’ll start by sharing some photos of the feeder disassembled.

The Auto Frozen Fish Feeder Disassembled

For the containers that will handle the food (Items A and C in the first diagram), you want to find something that has a funnel shape to it. This will assure the food settles near the bottom of the container which is where the dosing pumps tubes connect. In my case, I used an Iced Tea Bottle, installed upside down. The cap is the perfect size for the magnetic stir impeller. The other added benefit is it is easily replaced if/when the gunk builds up. I love Iced Tea so I don’t mind having another bottle to keep the feeder fresh and clean.

The top off water container (Item B in the first diagram) I used a Kamoer Dosing Container. It’s a large volume container and with its rectangular shape, it fits perfectly in the cooler.

The bottom of the cooler has egg crate that the Electronic Magnetic Stirrer sits on. Having the Stirrer up off the actual bottom of the cooler protects it from any accidental spill or liquid condensation that settles on the bottom. (NOTE: The more you open and peek into the Cooler, warm moist air will get into the cooler, and the more you will get condenstate dripping off the Cold Cooling Fins and containers)

Since we all have some Styrofoam lying around from our last fish or coral order, I discovered it works perfectly for mounting equipment and positioning things correctly and firmly in place. Just cut pieces to fit your varying conditions. Nothing is glued and installed permanently. As long as it fits snuggly it’s not going anywhere and it makes things easier to take apart for the occasional cleaning and/or maintenance.

I used wider diameter and stiffer RO tubing for the dosing line HOLDERS. Just cut some slits in the STIFF RO TUBING mentioned above and use a drop or two of hot glue to hold in place. The softer Air Line tubing will snap in. Try to keep from installing anything permanently as mentioned above. The same stiffer tubing was used to position the floppy tube at the bottom of the Concentrate Container in an effort to keep the tube on the bottom of the container at all times. This is important so it doesn’t get out of position during the stir.

Important to note, if you’re using tubing couplers you may need to enlarge the whole so you don’t end up with food getting lodged in the couplers. In my case, the couplers were too narrow so I drilled them out to enlarge the holes.

Don’t forget to enlarge the tube couplers if necessary

- Basically the Ice Tea Bottle is Inverted to hold the Thick Concentrate.

- Top of Bottle is cut open to add the Frozen Food and a small amount of Water.

- The Frozen Food will slowly settle to the bottom of the Container, and water will be at the top.

- The Magnetic Stir Pellet fits inside the Cap and it spins inside once the Magenetic Stirrer is activated. Mixing up the food and water.

Magentic Stirrer for the Frozen Concentrate Container Mixing

Now you don't want to just plug in the Stirrer and have it running all the time. You could but it's pointless, and it may grind and over liquify the frozen pieces.

So you need to turn it on every so often, and most importantly a minute before the Feeding Cycle starts. This will ensure the food concentrate is evenly distrubuted and each feeding is consistant. Otherwise your early feeding will be heavier, and the last feeding will be light. It's not perfect but that's the idea.

Since your Doser can't control the Magentic Stirrer, you can use a timer, and the program your stir and feed accordingly.

Magentic Stirrer Timer Options

Okay, so we have our Auto Feeder set up, it’s time to run the lines to the tank(s). Then you'll have to adjust your Flush program once you finalized the tube lengths to your tank. ( Remember the last program is the purge and is distance dependant )

This is my setup as seen from the Back of the Cooler.

Feeding Tube to Dosing Head Distrubution

You need to consider where the feeding output tube is installed in your tank(s). It’s important to make sure the food is either spread throughout the tank or I a feeding ring so the inhabitants can crab it before the overflow does.

I do have a feeding ring on one of my tanks so that’s where the output tube is installed. On another tank which doesn’t have a feeding ring, I placed the output tube right in front of a power head.

Feeding Tube Output Installtion Options (Above Water Surface or Below Water Surfice)

The other two tanks are too far from the auto feeder and would require a very long tube to reach them on the floor above the sumps. I’m lucky that both sumps are in the basement and close to the feeder. For those two, I simply placed the output tube (under water) next to the return pump inlet . The return pump takes care of the rest.

Feeding Output tube installed at the input of the return pump and the food is pumped to the tank Upstairs.

To close, I thought I’d share a couple ideas I had that I didn’t implement. I figured I’d share them in case a reader decides to build their own Auto Feeder and may be able to incorporate some different ideas. These additional concepts as well as designs other folks come up with can be discussed in the comments.

Simple Design (Downside, No Cleaning)

Complex DESIGN (Bi-Directional Doser Needed) for Reversing Pump Direction to Return Food to Reservoir.

Complex DESIGN (Bi-Directional Doser Needed) for Reversing Pump Direction to Return Food to Reservoir.

That covers off all I wanted to convey on the feeder design.

Summary:

I have been running the feeder for a couple of weeks and it works perfect. The longest I ran it unattended was 5 days while away from home, and it almost ran out of food and water. So I'm working fine tuning the Food Concentrate Concentration, and fine tuning the dilution and flush amounts to last longer.

The feeder airline tubes are perfectly clean with the flushing cycle, even my longest run which is 12 feet to my sump that sends food via the return pump to my upstairs tank.

The ONLY DOWNSIDE I see after running the Frozen Feeder for a while is the Fish have become trained on it, and now the fish love it more than me

I hope you have enjoyed reading about my adventure in creating a DIY Frozen Fish Feeder. It was a fun project and I’m sure as time goes on I will make adjustments to it. I would love to see what others have come up with for their own feeders. Feel free to ask questions and share your own projects.