Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Articles by Tenecor Aquariums

Filters

Show only:

Loading…

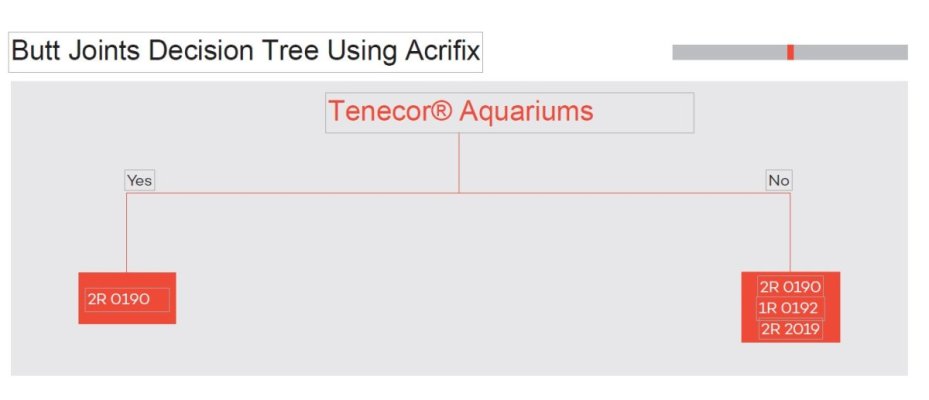

One of the most common questions we are asked is how to join two pieces edge to edge. This type of bond is called a "Butt Joint" and requires careful edge preparation, fixturing and patience. I will start with a guide on glue selection. For butt joining, we like to use Acrifix® products...

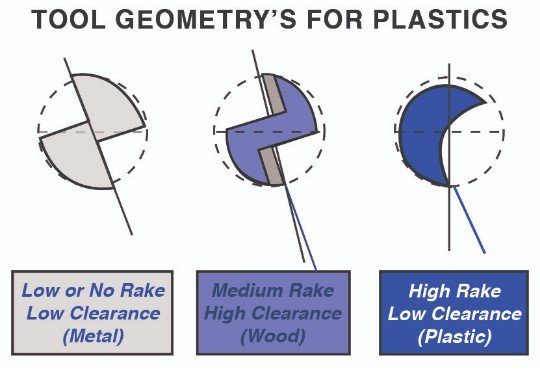

The two most common problems when cutting and routing acrylic welding of the material and poor edge finish. In this article, I will focus on routing. The top reasons for chip welding and poor finish are:

1) inappropriate tool selection

2) improper chip load

3) small tool diameter size

4)...

The gold standard for bonding acrylic to itself in larger aquarium builds is polymerizable cement bonding. It is the go to method when joining pieces greater than 1 inch in thickness and some cases, as thin as 1/2 inch. Polymerizable cements are those in which a catalyst is added to an already...

Before you continue, I suggest first reading this article describing the different bonding methods.

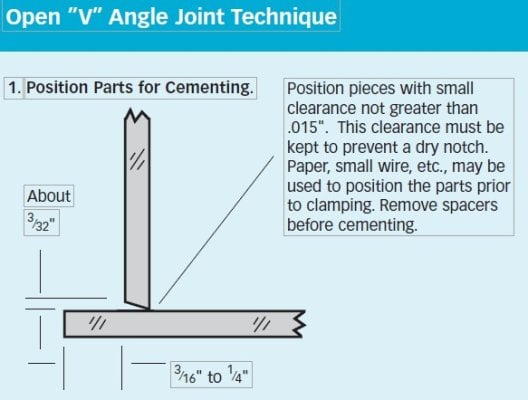

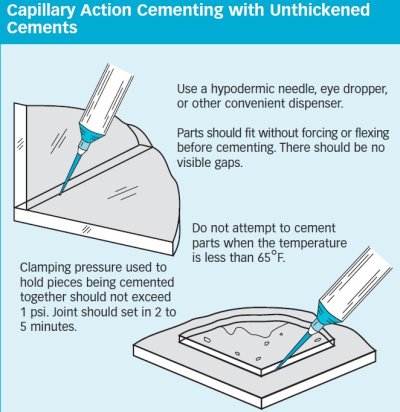

Capillary bonding is the most well known method for joining acrylic. And from the number of posts, easy to assume it is the only way. As in all methods, surface preparation is key to success. For...

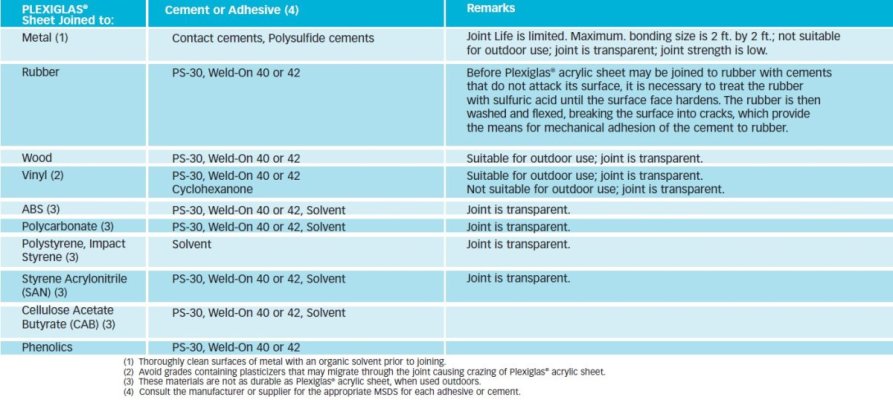

Satisfactory joints between acrylic sheet and other plastics as well as non-plastics are more difficult than joining acrylic to acrylic and the resulting joints are usually lower strength. In most cases, there is a substantial difference in thermal expansion between acrylic sheet and non-plastic...

Acrylic pieces may be joined three ways:

1) mechanical means such as bolts or screws

2) thermal means such as welding

3) chemical methods such as cementing

For our purposes, I will focus on the third method, cementing. There is a great amount of misinformation regarding this topic. The...

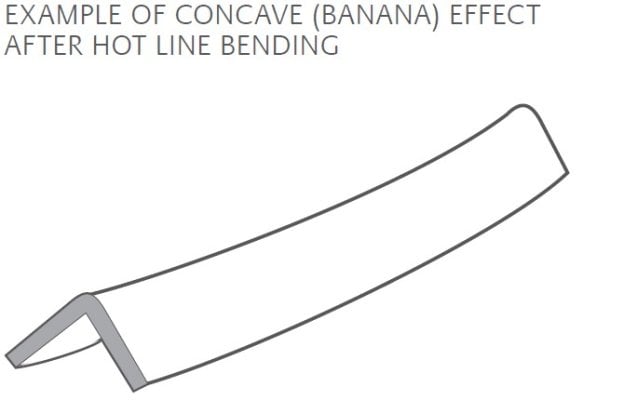

The simplest method of forming acrylic sheet along a straight line is to use a strip heater. Strip heaters are typically used to for the rapid production of simple boxes, and frames. They are generally limited to straight line bends. The process is usually used for small parts where the length...

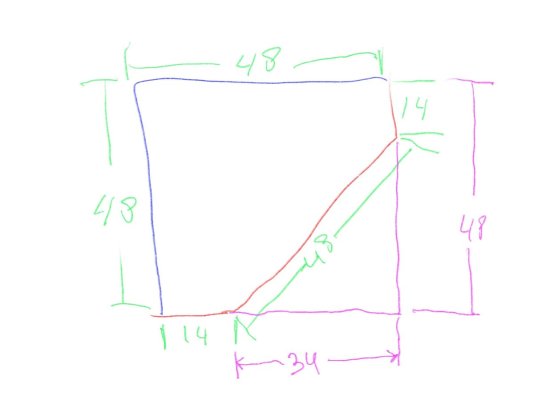

Corner pentagon aquariums have two symmetric back walls and a bent viewing panel. The back walls are at 90 degrees to each other and the viewing panel completes the vertical structure. The final assembly consists of a top and a bottom.

The challenge is the short leg dimension of the front...

Routers are used in edge-finishing operations and for cutting flat or formed acrylic sheet parts to size.

For our purposes, the two main types of router configurations I will discuss are 1) table and 2) portable. For edging small parts, the table router is convenient. When a part or assembly is...

Acrylic sheet can be cut in three ways:

1) Sawing

2) Routing

3) Scribing and breaking

Sawing and routing can be used for straight and curved cuts on any thickness of material. Scribing is limited to straight cuts in thin pieces of sheet .236 inches or less in thickness. It is practical for...

Hello everyone, There is a great deal of R2R interest in forming and fabricating with acrylic. There is also a great deal of misinformation. This is will be the first post, in a series of posts, discussing and explaining just about everything you ever wanted to know about working with acrylic...